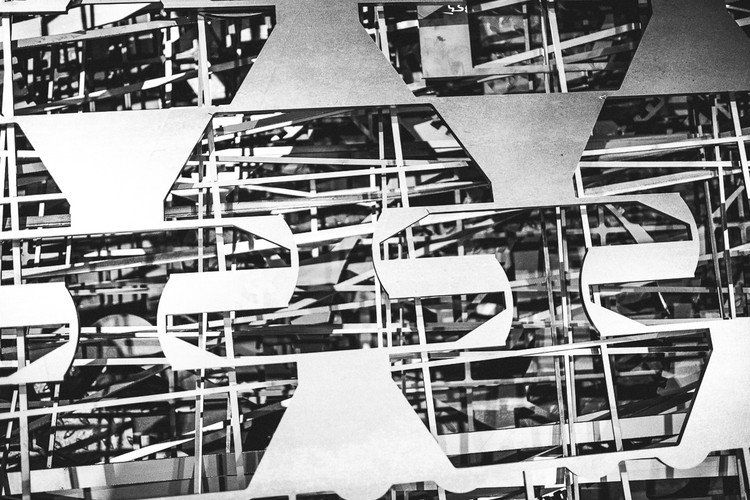

Sheet metal laser cutting

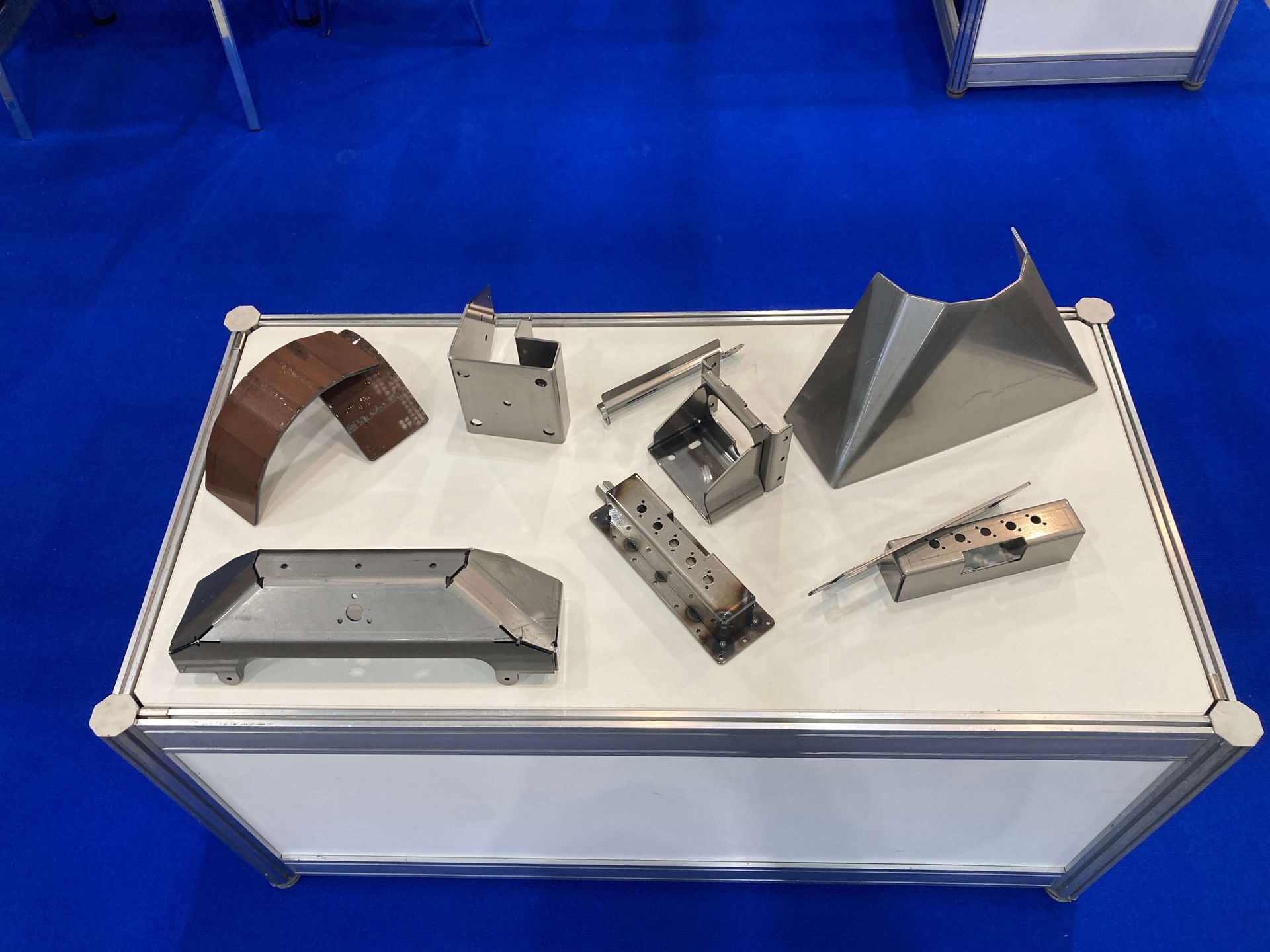

The CNC laser cutting machines owned by EMJ Metāls, Ltd. are capable of cutting up to 40 mm thick sheet metal, depending on the material type, grade, and configuration of the part to be cut. The technical specification of the machines allows the production of large parts, up to 8150 x 2600 mm, and to achieve remarkable metal cutting speed of up to 90 m/min. The tolerance to be achieved is +/- 0.1 mm. The company owns two CO2 and five “fiber laser” cutting machines, allowing our customers in all Europe to choose the most suitable technology depending on the type of material and the configuration of the part to be cut. We also can provide technical laser engraving services or laser marking of manufactured parts.

- As a subcontractor for sheet metal cutting and bending services, we have extensive experience in supplying prefabricated metal parts throughout Europe.

- Please send us your online manufacturing request today!

Our laser cutting mashines

The company uses two laser cutting technologies - CO2 and “fiber”. The largest machine has a cutting power of 20 kW and has a work table size of 2500x6000 mm.

| MANUFACTURER | TYPE | TABLE SIZE MM | CUTTING CAPACITY KW |

|---|---|---|---|

| BYSTRONIC | Fiber laser | 2600 x 8150 | 6 |

| Cutlite Penta | Fiber laser | 2500 x 6000 | 20 |

| EAGLE | Fiber laser | 2000 x 6000 | 10 |

| EAGLE | Fiber laser | 2000 x 6000 | 6 |

| TRUMPF | CO2 | 2000 x 4000 | 5 |

| TRUMPF | CO2 | 2000 x 4000 | 5 |

| BYSTRONIC | Fiber laser | 1500 x 3000 | 6 |

Talk to us today!

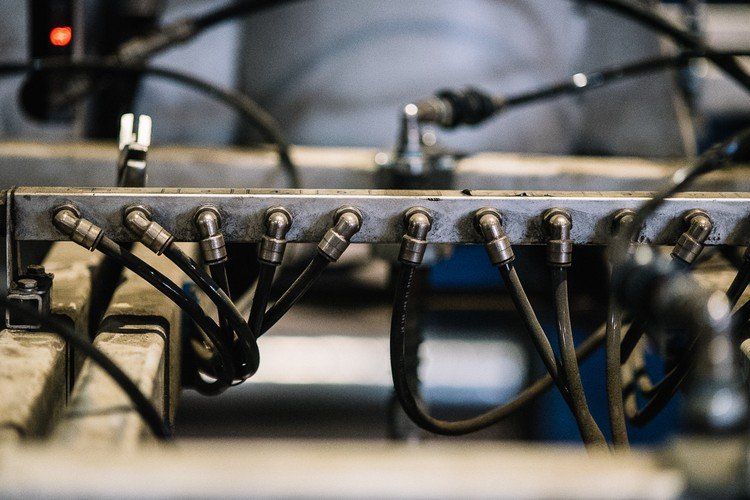

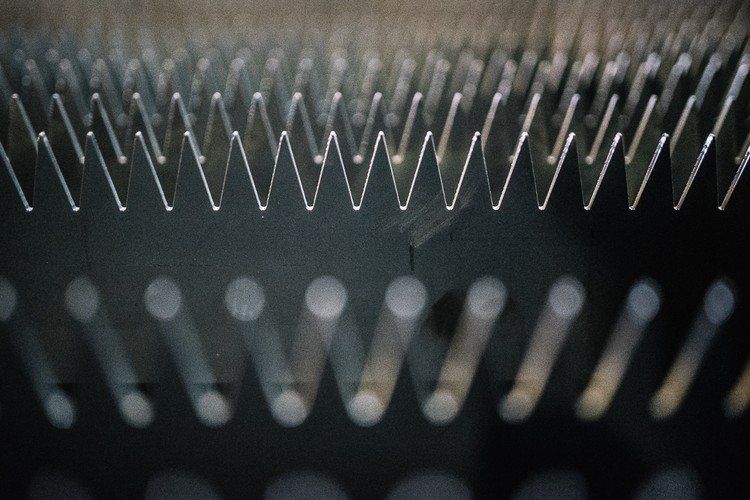

Metal parts bending with CNC

We carry out metal parts bending, using electrical, hydraulic CNC bending presses. Bending complexity, technical feasibility are detectable by seeing part drawings.

Plasma cutting

CNC plasma cutting is used to cut thick sheet metal parts, up to 60mm, that cannot be cut or are not cost-effective by laser cutting.

Metal parts CNC machining and aftertreatment

While we provide our core services of sheet metal fabrication, like laser cutting and CNC bending, we often find, that our customers are interested in additional CNC machining, drilling, threading, welding, grinding and coating operations.

Laser cutting process

Sheet metal laser cutting is a manufacturing process that uses a high-powered laser to cut or engrave materials, typically flat sheets of metal. This technique is widely used in various industries due to its precision, speed, and versatility.

Process Overview.

- Laser Source: The laser cutting machine utilizes a focused beam of light generated by a laser source (commonly CO2 or fiber lasers) to melt or vaporize the metal.

- Cutting Technique: The laser beam is directed onto the metal surface, often with the assistance of a computer numerical control (CNC) system, which allows for intricate designs and patterns to be cut with high accuracy.

- Assist Gases: During the cutting process, assist gases (such as oxygen or nitrogen) are used to improve the cutting quality, help remove molten material, and enhance the speed of cutting.

Materials.

- Laser cutting can be applied to a variety of metals, including:

- Mild steel

- Stainless steel

- Aluminum

- Copper

- Brass

- The thickness of the metal that can be cut varies based on the power of the laser and the type of material.

Advantages.

- Precision: Laser cutting offers high precision and can achieve tight tolerances, making it ideal for complex designs and intricate patterns.

- Speed: The process is relatively fast, allowing for high-volume production.

- Minimal Material Waste: Laser cutting can create intricate designs that maximize material usage, reducing waste.

- Versatility: It can cut a wide range of materials and thicknesses, making it suitable for various applications.

- Flexibility: Easy to switch between different projects by simply changing the design in the software.

Applications.

- Manufacturing: Used in the production of components for machinery, automotive parts, and appliances.

- Signage: Creating custom signs and decorative elements.

- Aerospace and Defense: Precision components for aircraft and military equipment.

- Electronics: Cutting parts for electronic enclosures and components.

- Art and Design: Used by artists for creating intricate metal sculptures and designs.

Limitations.

- Initial Cost: High-quality laser cutting machines can be expensive to purchase and maintain.

- Thickness Limitations: While lasers can cut a variety of thicknesses, there are practical limits based on the power of the laser and the type of metal.

- Heat-Affected Zone: The cutting process generates heat, which can affect the material properties around the cut edge.

Safety Considerations.

- Proper safety measures must be in place, including protective eyewear, ventilation systems, and fire safety protocols, as laser cutting involves intense light and heat.

Sheet metal laser cutting is a highly effective technique that combines precision with efficiency, making it a preferred choice for many industries. Its ability to create complex shapes with minimal waste contributes to its growing popularity in modern manufacturing processes.