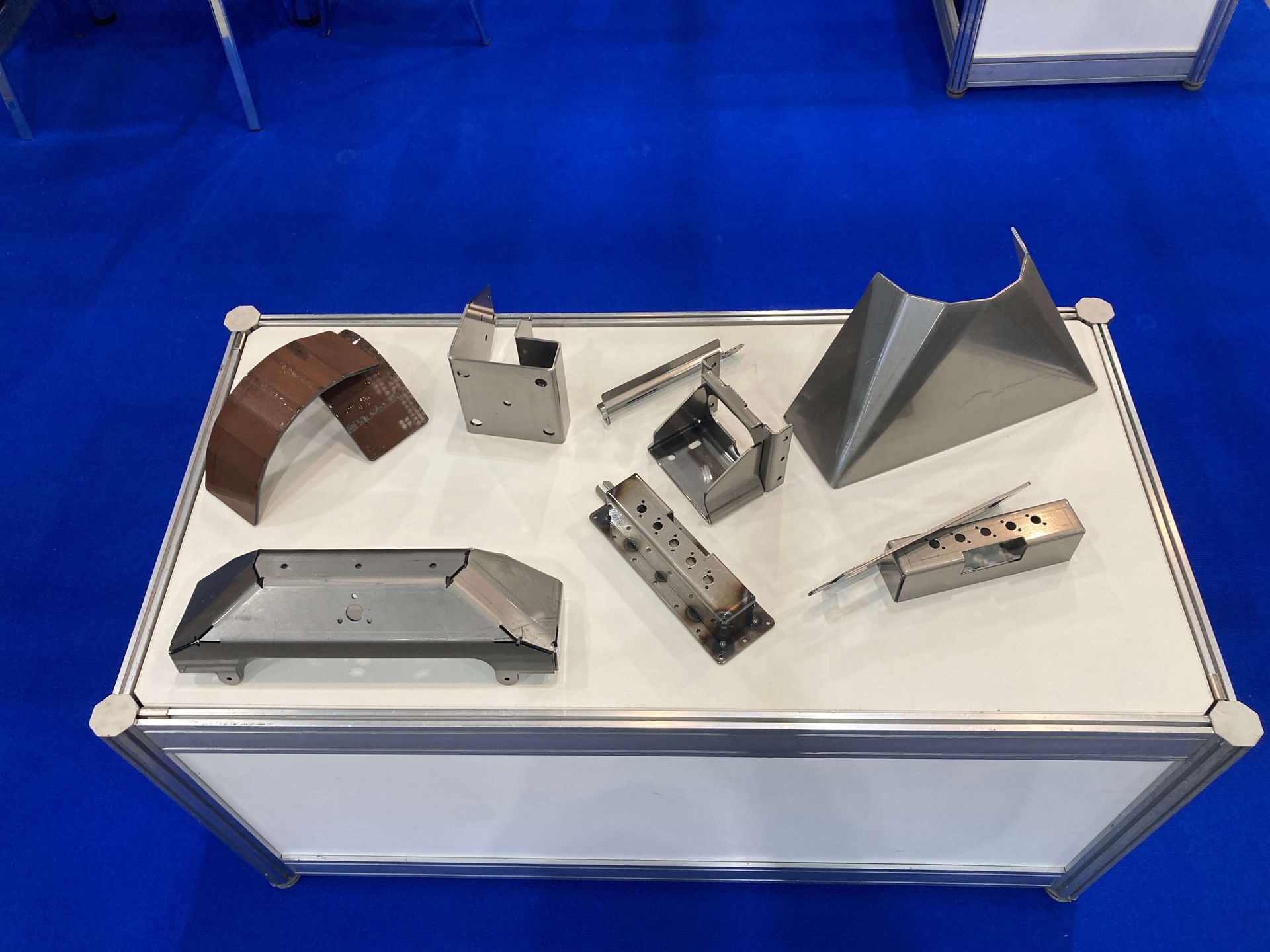

METALWORKING, SHEET METAL PROCESSING AND FABRICATION SERVICES

Sheet metal laser cutting

Our laser cutting equipment is able to cut materials up to 30 mm in thickness, depending on material type, brand and thickness. Estimated tolerance is +/- 0.1 mm.

Metal parts bending with CNC

We carry out metal parts bending, using electrical, hydraulic CNC bending presses. Bending complexity, technical feasibility are detectable by seeing part drawings.

Plasma cutting

CNC plasma cutting is used to cut thick sheet metal parts, up to 60mm, that cannot be cut or are not cost-effective by laser cutting.

Metal parts CNC machining and aftertreatment

While we provide our core services of sheet metal fabrication, like laser cutting and CNC bending, we often find, that our customers are interested in additional CNC machining, drilling, threading, welding, grinding and coating operations.

A reliable partner in metalworking.

Discover our sheet metal processing and fabrication services, powerful equipment, capabilities and range of operations. Metalworking is a passion for our company experienced team, who approach their tasks with a high sense of responsibility. By choosing us as your partner, you will benefit from:

- Reliable partner for the long term cooperation;

- Complete range of metalworking operations, from consultation to finished product;

- Individual approach to your project;

- Cooperation with experienced specialists in their field;

- High quality workmanship;

- Flexible and fast delivery dates;

- Affordable and competitive pricing.

Even if you don't find the service you need in the sections above, contact us, because we are constantly growing and developing, and may already be able to help you.

Enjoy the benefits of our metalworking services and cooperation with us! We export all over Europe.

Sheet metal processing services

Sheet metal processing services refer to a range of manufacturing techniques used to cut, shape, and assemble metal sheets into various components or structures. These services are crucial in various industries, including automotive, aerospace, construction, electronics, and HVAC (heating, ventilation, and air conditioning). Here are some key aspects of sheet metal processing services:

1. Processes Involved:

- Cutting: This can be done through various methods, including laser cutting, plasma cutting, waterjet cutting, and traditional shearing. Each method has its advantages based on material thickness, complexity, and precision requirements.

- Forming: Techniques such as bending, stamping, and deep drawing are used to shape the metal into desired forms. This can involve pressing the metal into molds or using machines to bend it at specific angles.

- Welding: Joining metal parts together through welding techniques like MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and spot welding. This is often necessary for creating assemblies or frames.

- Finishing: After forming and welding, finishing processes such as powder coating, anodizing, or painting are applied to enhance appearance, corrosion resistance, and durability.

2. Materials Used:

- Common materials for sheet metal processing include steel (carbon steel, stainless steel), aluminum, brass, copper, and alloys. The choice of material depends on the application, required strength, weight, and corrosion resistance.

3. Applications:

- Automotive Industry: Components like body panels, brackets, and chassis parts.

- Aerospace Industry: Aircraft parts, enclosures, and structural components.

- Construction: Structural supports, HVAC ducts, roofing, and siding.

- Electronics: Enclosures, chassis, and heat sinks.

4. Custom Fabrication:

- Sheet metal processing services offer custom fabrication to meet specific client requirements, including prototyping, small batch production, and large-scale manufacturing. Customization can involve unique designs, dimensions, and finishes.

5. Quality Control:

- Quality assurance is critical in sheet metal processing, with inspections and testing protocols to ensure that components meet industry standards and specifications. This can include dimensional inspections, stress tests, and surface quality checks.

6. Technology and Automation:

- Advances in technology have led to increased automation in sheet metal processing. CNC (Computer Numerical Control) machines and robotic welding systems enhance precision, efficiency, and production speed.

Online Sheet metal processing services play a vital role in modern manufacturing, enabling the production of a wide array of components and structures across various industries. The choice of processes, materials, and service providers can significantly impact the quality and functionality of the final products.

All Rights Reserved | SIA "EMJ metāls"