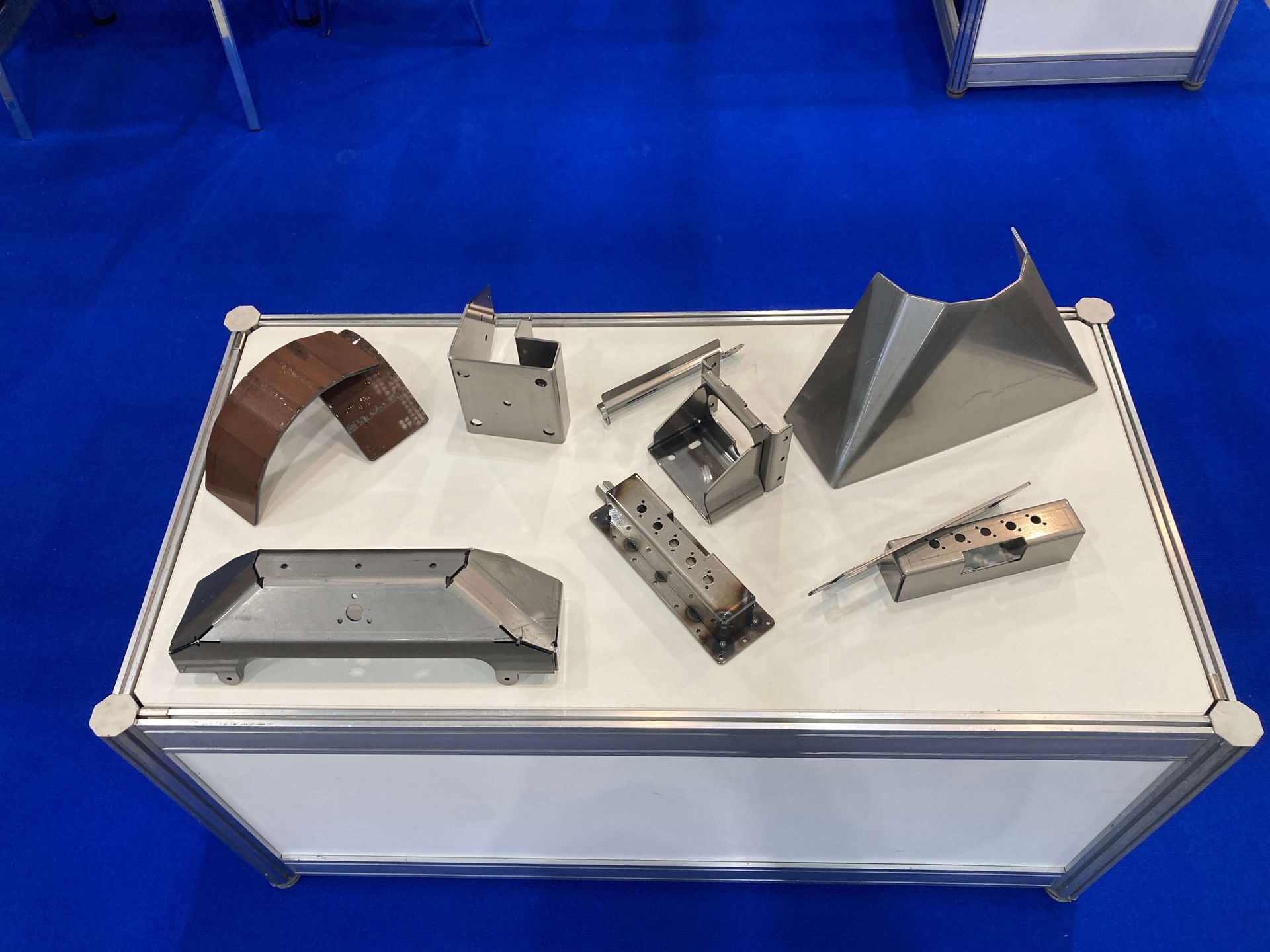

Metal bevel cutting with 3D plasma equipment

CNC plasma cutting is used to cut thick sheet metal parts, that cannot be cut or are not cost-effective by laser cutting. EMJ Metals plasma and oxyfuel cutting equipment can cut parts to a thickness up to 60 mm on a table size 20000mm x 4000mm. Our specialists will be pleased to help you with right choice, depending on your project specifications.

With our 3D plasma cutting equipment it is possible to cut the edges of sheet metal parts at an angle, bevel cutting in full or partial thickness, as well as from both sides of the part, making it easier to prepare parts for assembly or welding work.

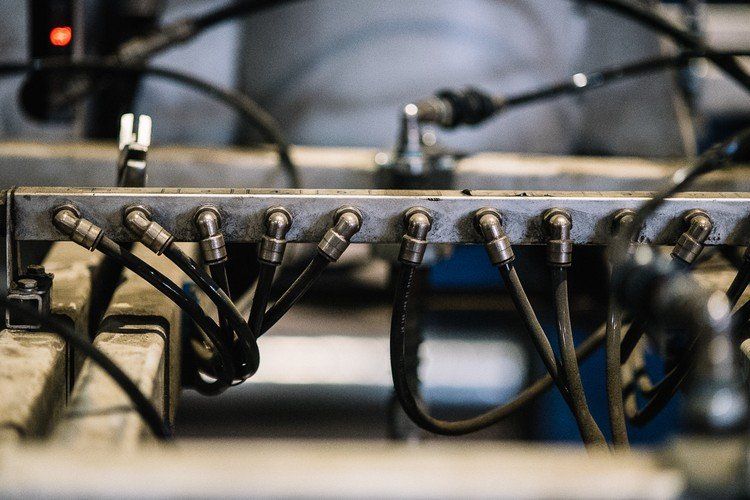

The machine is equipped with an additional CNC machining head, which allows drilling and threading of workpieces with diameters up to 35mm, or even much smaller diameter than the material thickness, directly on cutting table.

- As a subcontractor for sheet metal cutting and bending services, we have extensive experience in supplying prefabricated metal parts throughout Europe.

- Please send us your manufacturing request today!

Our plasma cutting machines

| MANUFACTURER | TYPE | TABLE SIZE MM | CUTTING CAPACITY KW | NOTICE |

|---|---|---|---|---|

| MICROSTEP | Gas / plazma | 4000 x 20000 | 400 A | Drilling, threading, bevel cut options |

| AJAN | Gas / plazma | 3000 x 6000 | 260 A |

The maximum metal cutting thickness up to 60 mm (upon prior approval)

Talk to us today!

We will get back to you as soon as possible

Please try again later

Metal laser cutting

Our laser cutting equipment are able to cut materials up to 30 mm in thickness, depending on material type, brand and thickness. Estimated tolerance is +/- 0.1 mm.

Metal parts bending with CNC

We carry out metal parts bending, using electrical, hydraulic CNC bending presses. Bending complexity, technical feasibility are detectable by seeing part drawings.

Metal parts CNC machining and aftertreatment

While we provide our core services of sheet metal fabrication, like laser cutting and CNC bending, we often find, that our customers are interested in additional CNC machining, drilling, threading, welding, grinding and coating operations.

All Rights Reserved | SIA "EMJ metāls"