THE LARGEST SHEET METAL PROCESSING AND FABRICATION COMPANY IN THE BALTIC STATES

Metalworking, sheet metal processing and fabrication company, EMJ Metāls.

We are a Latvian metalworking, sheet metal processing and fabrication company. We offer metal laser cutting, bending and folding and fabricated part aftertreatment services. Our end product is sheet metal parts: blank pieces made to the client’s individual or standard specifications. We have been working with sheet metal since 2010. Back then, we only had two clients and rented machinery. Today, our company has more than 20 large metalworking machines, serving more than 1000 clients every year and processing 40 tonnes of metal every day. We have extensive experience with projects of various sizes. The total floor area of our production facilities is more than 10,000 square metres. We are the largest provider of sheet metal processing, laser cutting and bending services in the Baltic states

Our clients come from a wide range of sectors, from civilian to the military production. For the military sector, SIA EMJ Metals provides a full production cycle, with metal cutting, bending, folding, welding, coating, etc.

Our main point of pride is the high potential and creativity of our team. Our current production machinery makes it possible for us to make parts with a total length of up to 8000 mm on-site. We have some of the most advanced laser cutting and bending equipment in the Baltics. We provide a safe and well-managed working environment for our employees, and our production facilities work 24 hours a day.

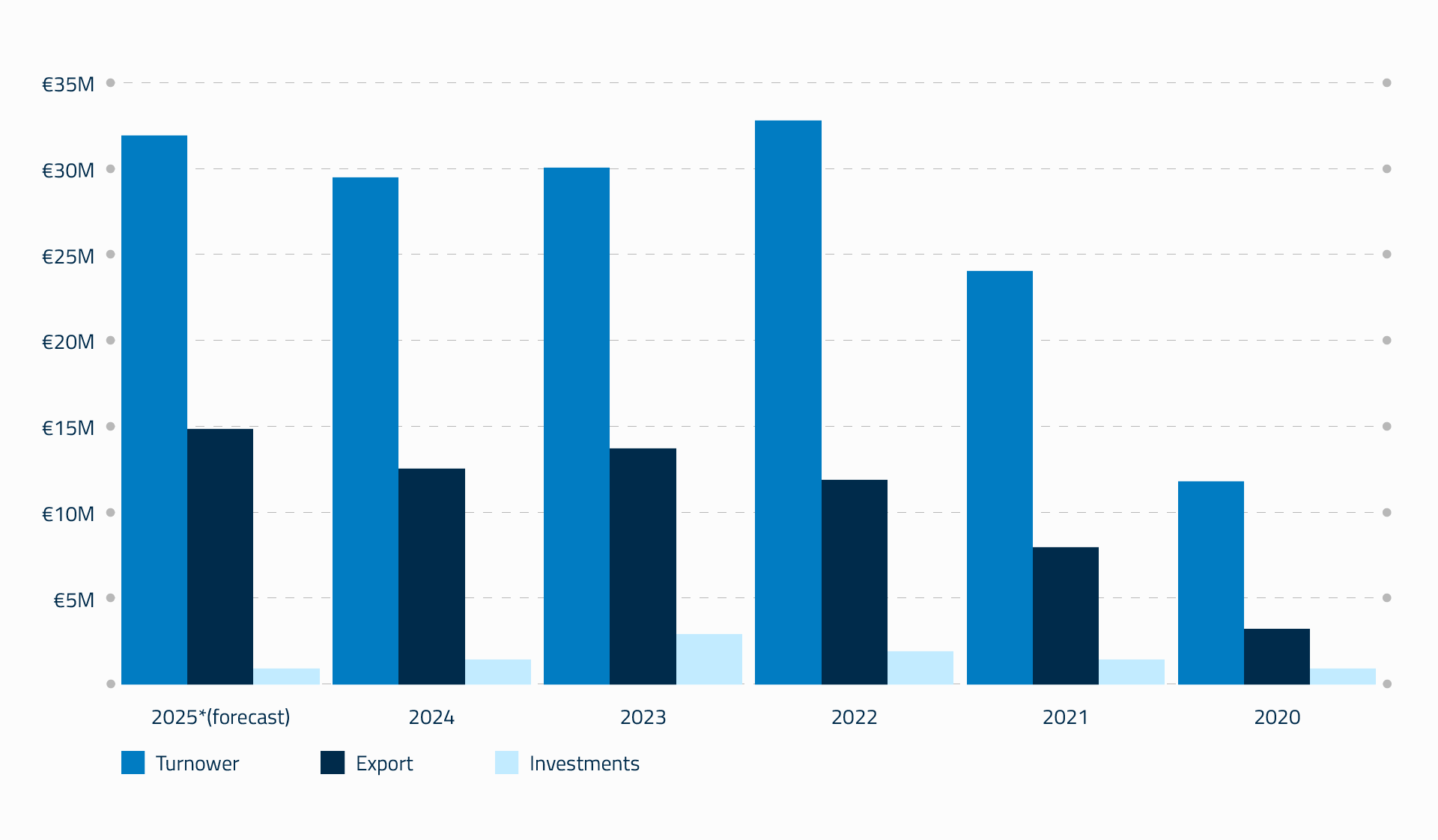

SIA EMJ Metāls grows thanks to the successful and long-term partnerships it has with its clients. Over time, it is not only the total number of clients that has grown, but also the demand among our regular clients, enabling us to develop and expand our activities, metal processing operations, and achieve new goals. The company has been doing management work in the industy since 2005.

Why us?

Metal laser cutting

Our laser cutting equipment is able to cut materials up to 30 mm in thickness, depending on material type, and brand. Estimated tolerance is +/- 0.1 mm.

Metal parts CNC bending

We carry out metal parts bending, using electrical, hydraulic CNC bending presses. Bending complexity, technical feasibility are detectable by seeing part drawings.

Plasma cutting

CNC plasma cutting machines are mainly used to cut thick sheet metal parts, that cannot be cut, or are economically unviable to cut by laser machines.

"EMJ Metāls" SIA participates in the Rehabilitation Fund project no. 5.1.1.2.i.0/3/24/A/CFLA/004 "Engineering cluster".

The goal of the project is to implement coordinated and targeted activities to strengthen the international competitiveness, exportability and innovative capacity of the members of the cooperation network, contributing to the development of the RIS3 field "Photonics and smart materials, technologies and engineering systems".

Project implementation period until 30.06.2026.